MOW

26-3

KERSHAW BallastRegulator 26-3

Skagway 2009, Boerries Burkhardt

Pandrol Jackson Model 950

Pandrol Jackson Model 950 Tie Crane

SN 151893, The heavy-duty 950 is designed to perform efficiently on both wood and concrete ties in high and low production tie replacement programs. The upper deck and workhead are capable of rotating 360 degrees in both directions making it very versatile. The articulate boom allows an 800 pound lift capacity 24 feet from center of track.

Length: Boom extended - 31' (9.44 m) Boom retracted - 20' (6.09 m)Width - 7' 6" (2.29 m) maximum Height - 14 2" (4.3 m), maximum w/ boom retracted Weight - 14,500 pounds (6591 kg) Ground Clearance - 3" (76 mm) Reach From Rail C/L - 14' (4.3 m) minimum - 24' (7.3 m) maximum Wheel Base - 6' (18.3 m) Construction - Upper deck & lower frame- rectangular tubing, channel, steel plate-wielded construction. Power Unit - John Deere Diesel 4039D water cooled engine Drive - Hydraulic motor driving both axles through chain reduction controlled by foot pedal. Wheels & Axles - 16' (406 mm) cast steel wheels fully insulated, mounted on 3" (76 mm) diameter axles. Single sprocket & hub on each axle driven by No. 80 chain. Brakes - Four-wheel fail-safe air with mechanical brake release capabilities. Emergency and parking brake is spring applied. Hydraulic System - Pressure compensated piston pump w/ delivery of 40 gallons (152 liters) per minute at 2300. All hydraulic lines are wire-braid hose. Electrical - 12-volt system, electric start. Gauges - Engine oil pressure and temperature, hourmeter, ammeter. Workhead - Rotates 360o powered by hydraulic motor. Standard head capable of handling one concrete or two wood ties at a time.Controls - Foot pedal and two joystick controls with pushbutton for operation of clamp cylinder. Tank Capacities Hydraulic tank - 60 U.S. gallons (230 liters) Fuel tank - 30 U.S. gallons - (150 liters)Standard Accessories - Manual hand emergency pump, open cab, dual tie head, tool box, horn, hoisting eye for lifting. Clearing Speed - 20 mph (32 km) Gradability - 3½% Load Capacity - 24 feet - 800 pounds (7.3 m- 365 kg). Load Capacity with bridge crane attachments - 10 feet - 4,000 pounds (3 m - 1,818 kg) Lift Above Rail - Maximum height - 13' (4 m) Lift Below Rail - Maximum depth - 15' 6" (5 m)Bridge Crane Attachment SpecificationsWinch - Hydraulic motor driven winch with lifting capacity of 4,000 pounds (1,818 kg) at a radius of 10 feet (3.05 m) from the centerline of the machine. Equipped with 5/16" (8 mm) cable, snatch block & hook. Rail Clamps - Fail-safe locking rail clamps on all corners of machine for safety. Tie Head Positioning Cylinder - Hydraulic cylinder attached in place of normal tie head. Stabilizing link to allow pre-positioning of the tie head while working. Controls - Manual hydraulic valve. Each function; rail clamps, wench & tie head positioning, individually controlled by separate hand lever. Rail clamp lever is detented and pinned for safety. Engine - Cummins 4B3.9 water cooled engine.

(All information from manufacture homepage)

Pandrol Jackson Model 2400

Pandrol Jackson Model 2400 Tamper

SN 151967 Skagway 2009

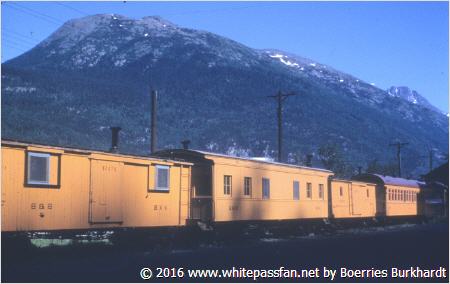

HISTORY - B&B Cars

Building & Bridge B&B Cars at Skagway

A number of work cars are waiting for another work. Skagway in the 1950's

CONTACT - The White Pass - July 1978

MAINTENANCE OF WAY

“Fair to good condition, some rough and bumpy sections, detours at intervals, “road condition report which is acceptable to those traveling on a highway, but it isn‘t good enough for a railroad.

Railroad must be in safe condition at all times whether there is one train a day or twenty trains using it and the 110.7 miles (178.15 km) of White Pass narrow gauge probably requires more attention than the average railway in North America.

To maintain these standards White Pass employs tour section crews, averaging six men to a crew, stationed Whitehorse, Carcross (one section crew north, the other south) and at Bennett. Kazemar Maczka who has been with White Pass since 1969 is in charge of the Whitehorse section, John Wally is section foreman for Carcross north, Walter Helm Carcross south, and He is still at work, Willie Scheffler. The Road Master for the Canadian section of the White Pass.

at Bennett.

A railroad bed consists of a base of gravel and rock, then about a foot and half (0.457 metres) of “ballast“ or crushed rock to a depth of 1 Y2 feet (0.457) to hold the ties which are placed about 22 inches (55.88 cm) apart. Fastened to the ties are the steel rails.

Every day the entire track is patrolled and section men acquire a sixth sense about the condition of the track, they learn to recognize any abnormal situation just from the feel of the motion of the track car or “Casey.“

There are 2978 ties to each mile (1.609 km) of track, 329,665 ties on the 110.7 (1 78.15 km) length plus sidings. Over these pound six trains a day in summer and tour in winter and they lowly press the ties into the gravel so the section men “surface” or raise them to a constant level.

Ties are perishable and the degree depends upon whether they are pine or the more durable fir, but as many as 12,000 ties may be replaced during a year.

Holding the rails in place on the ties are tie plates and these too must be checked for security. The rails are 36” (91 .44 cm) apart on straight stretches and 36.6” (92.96 cm) on curves. Any deviation can cause a derailment.

During subzero temperatures steel becomes brittle and cracks or breaks and has to be replaced. Conversely the heat of summer sun will cause the rails to expand to the point where “heat crinkles” will require the rail to be lifted and shortened.

A 30 foot (9.144 metre), 72 pound (32.659 kg) rail weighs 785 pounds (356.08 kg) and a 60 foot (18.288 metre) length of 100 pound (45.359 kg) rail weighs 2,000 pounds (907.20 kg). Replacing rail in winter is strenuous work.

To tourists on the trains the waterfalls cascading down the mountain flanks are scenic, to section men they mean culverts to be kept the track from being cleared in summer so as to keep the track from being washed out, and constant thawing of the ice formed in them in winter so the ice will not spill over the track. Freezing weather causes moist ground to heave so the section men remove the bumps, level the ties and rails, this is called “shimming”.

Besides clearing fallen trees, rocks and mud off the tracks, sidings have to be brushed; switches have to be kept cleared.

There are 22 bridges of varying lengths between Skagway and Whitehorse, some a few feet (metres) across a stream others high above deep ravines.

Section men go underneath each of these bridges periodically to check the approaches, bents and sills.

At any one time during the day there can be tour trains and six track cars on the track, and the biggest fear of course is a track car-train collision.

To keep dispatchers inform of their whereabouts section men carry field phone which are equipped to be hooked onto the telephone line between Skagway and Whitehorse to report their whereabouts and check on others.

During winter months snowfall between Mile 14 (km 23) and Mile 26 (km 42) may be up to 429 inches (1089 centimetres) or at least average 300 inches (762 centimetres). On twenty-four hour call are caterpillar tractor operators who trundle their D7 cats along the railway pushing snow off to one side or over the bank.

The company keeps four cats, one on standby near an avalanche prone area and three in operation. The most senior of the operators is Paul Cyr whom no one envies having to “walk” a cat across a high trestle bridge during a snowstorm.

Two ribbons of steel stretch from sea level at Skagway, up a mountain grade to an altitude of 2916 feet (888.80 metres) at Log Cabin, span ravines and rivers, wind around lake shores, disappear through snow sheds and tunnels, pass closed section houses and abandoned town sites, and parallel a brand new highway. Every day of the year someone patrols and examines checks and reports and he is called a section man, a member of the team who plays a vital role in safe Operations of the White Pass railway.

While this is the story of the section crews, Road Masters John Klein (Canadian section) and John Clarks (U.S. section) to whom the section foremen report are ultimately responsible for the condition of the railway.

This report is from the CONTACT - The White Pass - Magazine July 1978